[row]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

[/column]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

Egg Carton Making Machine

Model: BTF-5-8

Production/h: 4000-5000 pieces

Mold: 40

Total Power: 150 kw

Labor Force: 5-7 workers/shift

Voltage: 200V/380V

Template Size: 1.47m*0.47m

Overall Dimension: 3.1*3.7*3m-3.5*3.7*3m

Customization: Yes

[/column]

=====================

![]()

[/row]

Egg carton is aimed to packing eggs, before its invention, eggs were carried in egg baskets, but it is difficult to protect eggs from breaking, these cartons have a dimpled form in which each dimple accommodates an individual egg and isolates that egg from eggs in adjacent dimples. This structure helps protect eggs against stresses exerted during transportation and storage.

The main functionality of the egg tray making machine is protection of packaging eggs, convenient and practical. egg carton making machine should be able to reliably accommodate packing provisions of the eggs, the eggs are not damaged in the process of transport, handling, use, and itself to meet the requirements of strength, stiffness and stability.The raw material is safe, they do not interact.

The Making Process of the Paper Egg Carton Making Machine

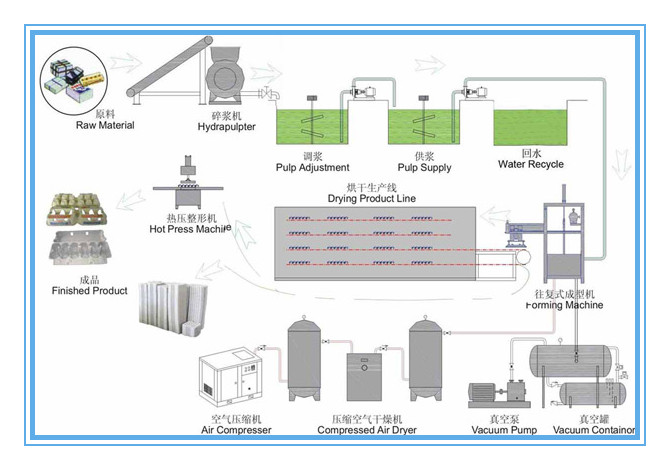

The egg carton production line includes three working systems: pulping system, forming system and drying system

Our egg carton making machine is the new packaging materials in recent years,The manufacturing process is raw materials pulping – ingredients – mold forming- drying – (shaping)-packing. After mold forming,the workpiece leaving a lot of water (approximately 55-60%) and the final product with a moisture content of 12-14%

Note:

As one of professional egg carton making machine manufacturers, our machines have been exported to many countries: South Africa, Philippines, Malaysia, Romania, Thailand, Indonesia, India and so on. if you want to know more, please Contact Us , we will give you answer ASAP.

The Technical Data of the Paper Egg Carton Making Machine

| Model | BTF-1-3 | BTF-1-4 | BTF-3-4 | BTF-4-4 | BTF-4-8 | BTF-5-8 | BTF-5-12 | |

| Production capacity | 1000 | 1500 | 2000 | 2500 | 3000-4000 | 4000-5000 | 5000-6000 | |

| Forming mould quantity (pieces/h) | 3 | 4 | 12 | 16 | 32 | 40 | 60 | |

| Total power (kw) | 34 | 41.2 | 53.7 | 57 | 90 | 150 | 153 | |

| Electricity consumption (kw/h) (70% of the total power) | 23.8 | 28.84 | 37.59 | 39.9 | 63 | 105 | 107.1 | |

| Labor force | 3-5 | 4-6 | 4-6 | 4-6 | 5-7 | 5-7 | 5-7 | |

| Materials consumption (kg/h) | Paper | 85 | 102 | 170 | 212 | 298 | 425 | 459 |

| Water | 255 | 306 | 510 | 636 | 894 | 1275 | 1377 | |

| Fuel consumption | Coal | 50 | 60 | 83 | 104 | 125 | 208 | 208 |

| Natural gas | 22-32 | 26-36 | 37-47 | 46-56 | 56-66 | 92-103 | 92-103 | |

| Diesel | 18-28 | 22-32 | 30-40 | 38-48 | 46-56 | 77-87 | 77-87 | |

Case Show

[row]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

[/column]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

[/column]

[/row]