[row]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

[/column]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

Apple Fruit Tray Making Machine

Model: GLF-4-4

Output per hour(pieces): 2200-2500

Mould quantity: 16units

Total power(kw): 65

Paper consumed per hour(kg): 110-175

Pulper power(kw): 7.5

Customization: Yes

==============================

![]()

[/column]

[/row]

Beston paper tray making machine can make all kinds of shapes according to your usage. such as egg trays, fruit trays, coffee cup trays, bottle trays etc. The capacity of the completed production line is 400pcs/hour – 28000pcs/hour. these bring big convenient for our life, such as fruit trays can help us store fruits better, prevent fruits from collision and extrusion.

[row]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

[/column]

[column lg=”6″ md=”12″ sm=”12″ xs=”12″ ]

[/column]

[/row]

The Working Process of the Paper Apple Fruit Tray Making Machine

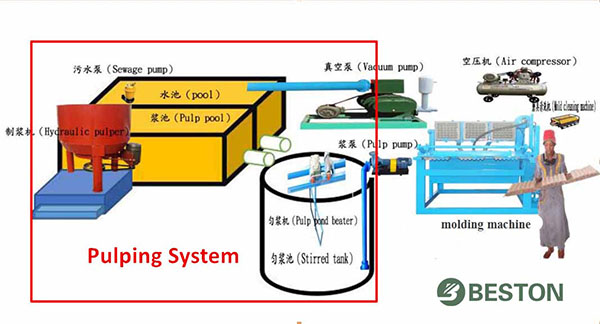

Paper apple fruit tray making machine is consist of pulping system, molding system, drying system and packing system.

1.First, placing the raw materials, water and additives into hydraulic pulper proportionally,

2.Then, pulping system and molding system will work based on the presupposed procedure.

3.We can produce different products with different molding dies.For instance, egg tray, fruit tray, shoe tray, electric tray,

Note:

Apple tray making machine is also acceptable for making various fruit or vegetable trays with different capacities. We have formed a multifunctional pulp molding production line with dismountable pulp molding dies. And the molds are easy to assemble and disassemble. if you are interested in pulp molding machine to making fruit tray, please do not hesitate to Contact Us , we will give you a prompt reply.

The Technical Data of the Paper Egg Tray Making Machine

| Model | Output | Mold | Total power | Labor force | Paper consumption/h | Vacuum | Pulper | Drying |

| (pieces/h) | equipment | |||||||

| BTF-1000 | 1000 | 3 | 33 kw | 3–5 | 60 kg | 7.5 kw | 7.5 kw | 5.5 kw |

| BTF-1500 | 1500 | 4 | 49 kw | 4–6 | 87 kg | 11 kw | 7.5 kw | 16 kw |

| BTF-2000 | 2000 | 6 | 37 kw | 4–6 | 120 kg | 11 kw | 7.5 kw | 7.5 kw |

| BTF-3-4 | 1800-3000 | 12 | 40 kw | 4–6 | 100-200 kg | 18 kw | 7.5 kw | 15 kw |

| BTF-4-4 | 2200-2500 | 16 | 65 kw | 4–6 | 110-175 kg | 22 kw | 7.5 kw | 19 kw |

| BTF-3-8 | 2000-4000 | 24 | 72 kw | 5–7 | 110-260 kg | 29 kw | 7.5 kw | 19 kw |

| BTF-4-8 | 4500-6500 | 32 | 85 kw | 5–7 | 110-260 kg | 29 kw | 7.5 kw | 19 kw |

| BTF-5-8 | 5000-7000 | 40 | 110 kw | 5–7 | 270-450 kg | 47 kw | 22 kw | 21 kw |

| BTF-4-12 | 5000-7000 | 48 | 160 kw | 5–8 | 300-600 kg | 55 kw | 22 kw | 26 kw |

| BTF-5-12 | 6000-9000 | 60 | 180 kw | 6–9 | 350-750 kg | 75 kw | 30 kw | 37 kw |

Four Different Drying System You Can Choose

1.Natural Drying: If you a small budget investor, and the local weather in your country is good, such as high temperature, suitable wind, you can choose to dry wet egg tray under the sun.

2.Brick Drying Room with Carts: After manufacturing egg/fruit trays, the worker need to put the egg/fruit trays on the small cart. Then, convey the wet egg/fruit trays to brick drying room

3.Brick Drying Room with a Conveyor Belt: save labor & high efficient.

4.Metal Drying Room with a Conveyor Belt: Automatic to convey the wet egg/fruit trays to metal drying room.